Gravel-less Soil Dispersal Systems

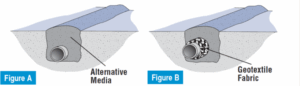

As the name suggests, a gravelless system is an onsite system that does not use gravel in its drainfield trenches or beds. Instead, these systems may use alternative materials in place of gravel, such as rubber, sand, fiber membrane, plastic, glass, or expanded clay, shale, or polystyrene foam chips. The alternative media in gravelless systems can function similarly to gravel. It can support the sidewalls of the drainfield trenches and prop up the perforated drainfield pipes so they don’t lie directly on the soil and clog. When soil is saturated from the weather or surge wastewater loadings occur, the effluent can be stored in the media until the soil absorbs it. Like gravel, the alternative media also can help to distribute the wastewater along the length of the trenches. In some gravelless drainfields, wrapped or slitted corrugated pipe is used instead of an alternative media material. One gravelless drainfield design consists of large, corrugated plastic pipes, with inside diameters of 8 to 10 inches, covered with a geotextile fabric or a spun bonded nylon filter fabric. The effluent infiltrates the areas of the soil that come in contact with the fabric.

Gravelless pipe systems should include a cleanout to allow the pipe to be inspected and for any sludge that may accumulate in the pipe to be flushed out. Chamber systems, which are discussed in more detail beginning on page 5, are another popular type of gravelless system.

Like conventional drainfields, gravelless systems can be designed to work on a variety of homesites and under most conditions. Some studies suggest that they may perform better than gravel-lined drainfields. These systems also require the same maintenance as traditional drainfields. Homeowners should first check with their local health department about local and state regulatory requirements (refer to the contacts list on page 7 and to page 6 for state requirements). Also, most communities require a professional site evaluation be performed to assess the appropriateness of the site for any onsite system.

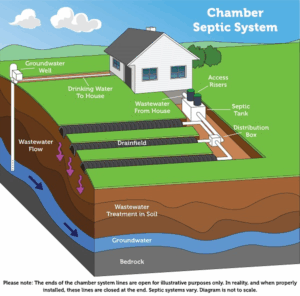

Chamber systems, sometimes called leaching chambers, are a type of gravelless drainfield becoming increasingly popular. Chamber refers to the open-bottomed pipes used in these systems. They are commercially available and usually constructed of high-density plastic. Chambers also may be constructed of fiberglass, block, or brick.

The chambers are molded into a dome-like shape (refer to the figure below and on page 1). Their design usually is proprietary and manufacturer recommendations should be followed regarding system installation, design, operation, and maintenance.

Leaching chambers are manufactured in widths varying from 15 to 40 inches. Although some chamber systems are constructed of light-weight material, they are strong enough to support a soil cover and normal backyard activities. However, as with any onsite system, homeowners should prevent anyone from driving, paving, building, or placing heavy materials on top of the system.

Because some chamber panels are light weight, installers can manually carry and place them in level trenches. Chamber panels are designed to interlock, and they may be fastened by screws at the interlocking connections. Some designs interlock without the use of screws or other fasteners, further reducing installation time and costs.

Backfill, composed of native soil or other porous material the manufacturer suggests, is placed along the sides of the chambers and usually is compacted just enough to add support to the dome structure. Each system should include at least one inspection port to allow water levels in the chamber to be monitored.

A 4-inch pipe transports effluent from the septic tank or other treatment unit to the chambers. Although some systems are designed with perforated distribution pipes within the chambers (see the graphic below), pipes are not necessary within the chambers themselves. Geotextile fabric also is not needed around the chambers or pipes. The wastewater enters the chambers and is absorbed and treated by the soil below.

A chamber system is appropriate for any site where a conventional drainfield is appropriate. These systems also can be used on sloped and wooded sites inaccessible to heavy equipment. Distribution devices can channel wastewater between chamber segments at different elevations as is possible with gravel-lined systems.

Because they are easy to install, chamber systems often are an attractive choice for homeowners who wish to minimize the type of damage to landscaping that heavy machinery can cause. In addition to being light weight, some chambers are stackable, making them less expensive to transport. Their easy installation also may reduce labor costs.

Chamber systems have many of the same advantages as other types of gravelless systems. For example, there are no problems with clogging from dust and fines because gravel is not used. Chamber systems also are very flexible. They can be reconfigured and adapted to different features of the lot, and the systems can be easily expanded and even relocated if necessary—an option not easily available with conventional systems.

Perhaps the most significant advantage of chamber systems is they can store a large amount of effluent. This feature becomes especially important for onsite systems that frequently experience surge or shock loadings (for example, from running toilets or leaky fixtures, extra house guests, or periods of heavy rains). However, while a large storage capacity is helpful when dealing with shock loadings, prolonged periods of effluent storage can be detrimental to soil performance.

In addition, several states allow drainfield size reductions for chamber systems even when they do not allow them for other types of gravelless systems (refer to page 6). Smaller drainfields mean lower construction costs. This is an important advantage for property owners with small lots.

Cost is the most significant drawback with chamber systems. Except in those areas where high-quality gravel is expensive or hard to come by, gravel-lined systems usually cost less overall. However, reduced labor and transportation costs may offset higher material costs with chamber systems. Homeowners who are considering installing any type of gravelless system should first compare prices with those for conventional gravel-lined systems.

| Source: PIPELINE – Summer 2001; Vol.12, No.3 National Small Flows Clearinghouse |